Blister detection

- In-line blister detection for profile wire

Blisters are bulgy defects on the surface of the insulation layer that typically occur due to faults in the production processes, and DSE Test Solution offers two types of inline blister detection solutions:

-

BDU - Blister Detection Unit

-

BMS - Blister Measurement System

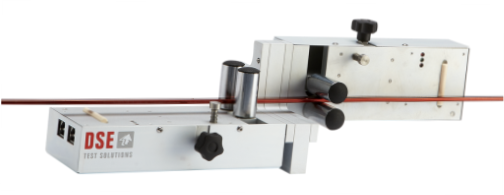

Blister Detection Unit - BDU

The Blister Detection Unit is a high-precision, non-destructive device made for detecting blisters in the flat enameled wire during manufacturing. It detects blisters on all four sides of the wire down to 50μm. In case a blister is detected, the data is stored either locally or on a server.

Check out the datasheet for further information on the Blister Detection Unit here.

Blister Measurement System - BMS

We can offer the Blister Measuring System if additional information and evaluation on the specific blisters is required (e.g., requirements from the automotive industry and other demanding applications).

Besides counting the number of blisters and storing the data as the Blister Detection Unit, this solution detects blisters on all four sides of the wire down to 30μm.

Furthermore, it measures the actual height and length of the blisters, possibly making a threshold level of the blister size and generating related alarms.

You can read the datasheet for the Blistering Measuring System solution here.

Quality check of the wire

The BDU and the BMS solutions can operate as independent, standalone inline blister detection solutions and provide the necessary documentation on the wire quality.

To provide a complete quality check of the wire, you can use our High Voltage Continuity solution and our High Voltage Continuity solution to detect pinholes and weak spots in the wire insulation.

For more information, please get in touch with our sales department or read the datasheet.