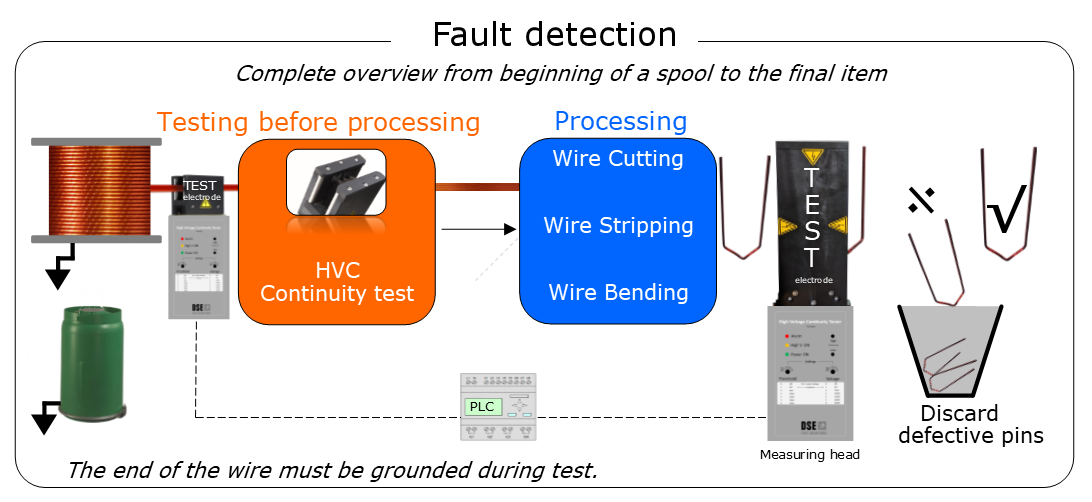

In-line continuity test for manufacturing hairpins

Quality check of manufactured hairpins

Manufacturing hairpins is demanding, and the strong bending pushes the enamel to the limit.

The way to go is to ensure that every hairpin leaves the manufacturing line with an individual test of each item.

Doing a pre-test means knowing the wire quality before wire processing.

You can use a high voltage continuity tester (HVC) to detect enameled wire that is not 100% coated or has cracks or pinholes. Read more about pinhole detection here.

Blisters on the wire's surface also cause problems and significantly impact the quality of the hairpin and the final stator.

Read more about blister detection here.

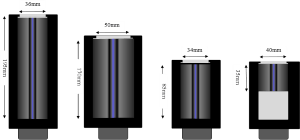

Our HVC 360 SA - is explicitly designed for hairpin producers

-

- Simple installation

- Operates without PC

- Settings directly on the unit

- Analog interface for PLC

- LED indicators on the front

- Detected fault output signal

- Tailor-made for end users of wire

The new HVC 360 SA measuring head offers the wire's end user an effective way to detect defects such as pinholes or cracks in the insulation before processing starts.

Hairpin winding

Adding this measuring head before winding a stator, rotor, coil, transformer, hairpin, etc., ensures that the final product is not turned into scrap due to missing or insufficient insulation of the wire. Checking missing overlap for wrapped wire is also possible.

FAQ

##

How is it possible to test hairpins for electric motors?

The possibility of testing hairpins for electric motors is continuously developing, and we are at the forefront of quality and technology in this field.

We use our HVC Stand-alone, with our specially designed electrode tops with conductive brushes, to test every single hairpin to ultimately lower the amount of scrap and time wasted. Our HVC system will measure even the tiniest cracks and faults in the enameled wire and is often built into an automated system.

Why and when should we test the hairpins for our electric motors?

With our HVC test system, we are able to test and ensure quality at the most critical and appropriate time in the manufacturing process, saving time and costs and minimizing scrap. Hairpins will only leave the production line if they are individually tested and approved or discarded, ultimately making it more efficient and providing documentation that the hairpins are approved.

Can I test I-pins with DSE's test solution?

Yes!

To ensure we cover all the areas of testing enameled pins, we have also developed a system that can be added to our electrode tops for hairpins. This add-on will create a gap between the brushes and the electrode top, where the uninsulated area of the I-pin can run through without the brushes testing that specific area. The system only tests the insulated area of the I-pin for faults and cracks. Therefore, it is an effective solution for testing I-pins in an automated process.

###

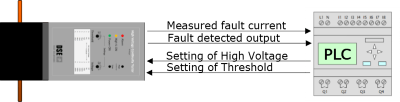

Complete control from PLC - no PC needed

When many winding machines are running with different applications, a PLC control is a more practical way of controlling and outputting data. Direct access to detected fault output also makes it possible to stop the winding process or mark the wire.

Simple in installation and simple in operation

Only 24 VDC is needed. The High Voltage and Threshold setting is done on the front using five individual pre-sets (other pre-sets can be made on request) or an analog interface [0.. 10 VDC] for making settings and fault current measurements.

Features of the HVC measuring heads:

-

- Full 360-degree surface coverage of the wire

- Build-in controller with five individual pre-sets for both the High Voltage tension and threshold

- Interface for PLC, direct setting of HV, and fault current/threshold from [0.. 10 VDC]

- Output for measured fault current

- A wide range of electrodes is available, from wire size 8 µm to a completed bent hairpin

- Optically isolated output when a fault is detected

- Output for switch on light tower (Power ON & High Voltage ON)

- No damage from sparks (low power design)

- Wide output test Voltage range 350 VDC to 6000 VDC

- Low tension means no damage to the enamel because of the very soft conductive brushes

We use feedback from our clients and the market to develop our solutions. Feel free to browse our website and find out more in the datasheet. If you’re worried that we might not have a solution for your setup, please contact us, and we will do our very best to use your feedback as fuel for further development.

Download the datasheet here

Read our case here

Read more here:

English version Deutsches Version

|

|